The Active Window System is a new window system that aims at changing the traditional window concept to an active element that promotes energy efficiency, indoor air quality and user comfort. This new window system is based on the following technological pillars:

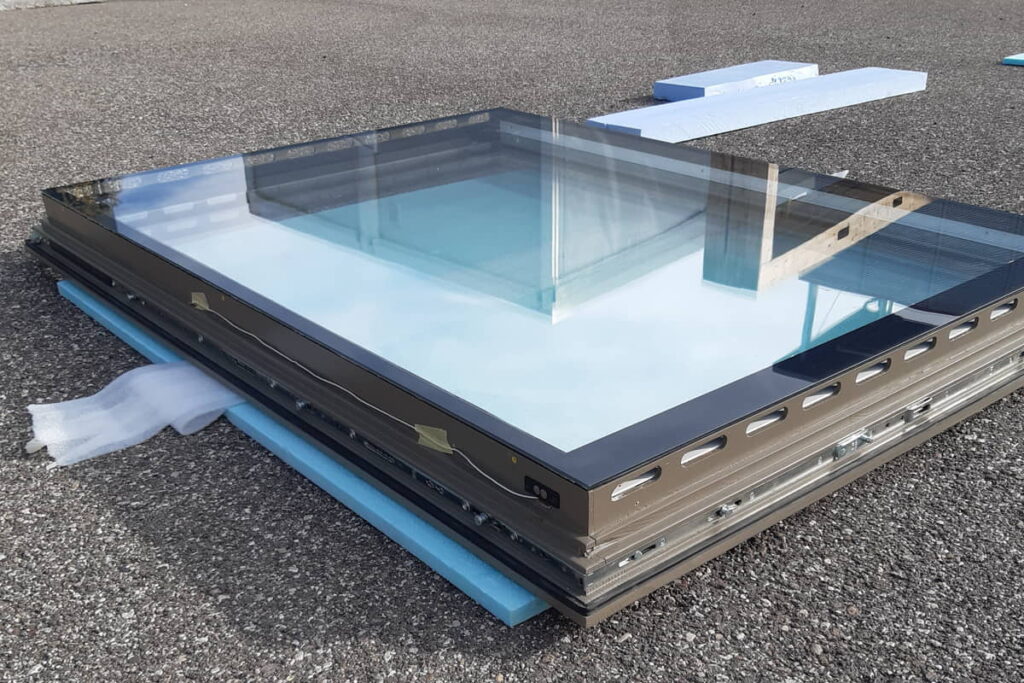

- Modular wood frame system: The wood frame new design was conceived to be easily adaptable to different configurations, such as different climates, different insulating glazing units (IGU) or integration of different shading devices. It was designed to be easy to manufacture and to install both, in-wall and insulated block installation.

- Movable adaptive shading system: The AWS can integrate different shading systems, such as external shading, electrochromic glass or integrated venetian blinds. In the latter case, the venetian blinds are allocated in a semi-ventilated external chamber in front of the insulating glass unit and protected by an external openable glass. This configuration allows to easily maintain the system.

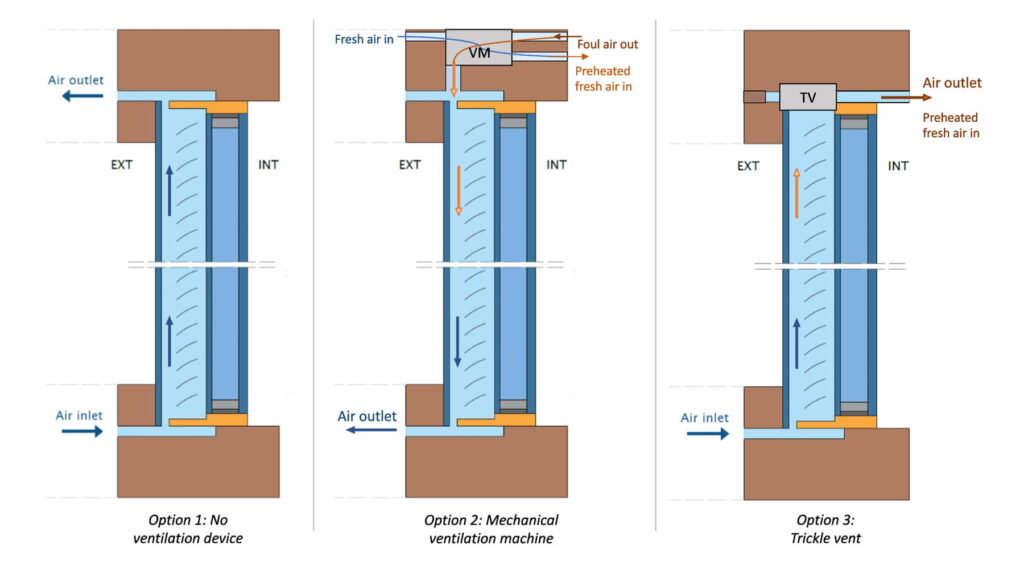

- Integrated decentralized ventilation device: The AWS, as a multifunctional window system, allows the integration of decentralized ventilation devices, such as passive trickle vents for assuring certain natural ventilation or active compact mechanical ventilation machines with heat recovery.

- Interaction between shading semi ventilated cavity and decentralized ventilation device: The most advanced configurations of the AWS include the venetian blinds in the semi ventilated cavity and the ventilation device in a way that they collaborate with each other, with the aim of exploiting the shading cavity ventilation for optimising indoor air quality and energy consumption. This could be done in different ways depending on the type of ventilation device (passive or active) and the season.